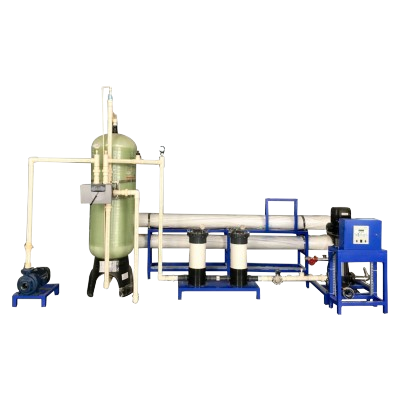

500 litter RO Plant

A 250 LPH (liters per hour) industrial RO (Reverse Osmosis) system is a water purification unit designed to remove impurities, dissolved salts, and other contaminants from water by passing it through a semi-permeable membrane. This system is typically used in industries requiring high-quality water for processes like manufacturing, cooling, or even drinking water production.

Key Features of a 250 LPH Industrial RO System:

- Capacity:

- The system can purify 250 liters of water per hour, making it suitable for medium-scale industrial operations or for use in small factories, workshops, or offices.

Read More

- Reverse Osmosis Membrane:

- The heart of the system is the RO membrane, which works by applying pressure to the water and forcing it through a semi-permeable membrane, allowing only water molecules to pass while rejecting contaminants.

- Pre-filtration:

- Before the water reaches the RO membrane, it usually passes through pre-filters, such as sediment filters and activated carbon filters, to remove larger particles, chlorine, and organic contaminants that could damage the RO membrane.

- Post-filtration:

- After the water has passed through the RO membrane, additional filtration might be applied (such as UV or activated carbon filters) to ensure any remaining impurities are removed, and the water meets the required purity standards.

- Recovery Rate:

- The recovery rate of a 250 LPH system is typically around 50-75%, meaning the system can recover that percentage of the input water as purified water, with the rest being rejected as waste (brine).

- Waste Water Management:

- The rejected water (concentrate) is often disposed of, and it’s important to manage this waste properly, especially in industrial settings where it can contain contaminants.

- Control Panel:

- The system typically comes with a user-friendly control panel for monitoring key parameters such as pressure, flow rate, and water quality. Some systems may also have alarms to indicate issues like low pressure or fouling.

- Applications:

- Food and Beverage Industry: For processing clean water for product formulation or equipment cleaning.

- Pharmaceutical Industry: For producing pure water used in drug production.

- Manufacturing: Used for cooling towers, boilers, or other manufacturing processes requiring clean water.

- Drinking Water: Some systems are designed for producing potable water, especially in areas with poor water quality.

- Maintenance:

- Regular maintenance is required, including cleaning of filters and membranes, replacement of consumables like pre-filters, and periodic checks for performance optimization.

- Energy Efficiency:

- Modern industrial RO systems come with energy-saving features to reduce operational costs, including energy recovery devices that recapture energy from the brine stream.

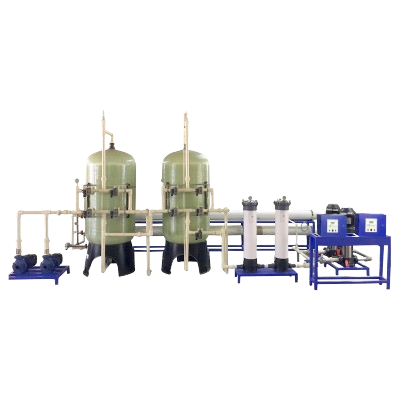

4000 LPH RO

The specifications for an Industrial Reverse Osmosis (RO) System with a capacity of 4000 LPH (Liters Per Hour) can vary depending on the brand, model, and intended use. However, here are some general specifications you might find for such a system:

General Specifications for Industrial RO 4000 LPH:

Read More

1.Capacity:

4000 LPH (Liters Per Hour)

Membrane:

Membrane Type: Thin Film Composite (TFC)

Membrane Size: Typically 8” x 40” or 8” x 60”

Number of Membranes: Around 2 to 4 depending on design

Recovery Rate:

Typically 75% to 85% recovery (i.e., percentage of influent water that is converted to purified water)

Feed Water TDS (Total Dissolved Solids):

Typically ranges from 500 to 5000 ppm (parts per million), depending on system design

Operating Pressure:

Typically ranges from 6 to 14 bar (90 to 200 psi) depending on the water quality and type of membrane used

Pump:

High-Pressure Pump: Usually a centrifugal or piston pump rated to handle the required pressure (often in the range of 5 HP to 15 HP depending on capacity)

Pump Type: SS (Stainless Steel) or FRP (Fiber Reinforced Plastic) depending on application

Pre-treatment:

Multi-media filters (sand, anthracite, etc.)

Activated carbon filters

Softener: For removing hardness (if required)

Antiscalant dosing system: To prevent scaling on membranes

Post-treatment:

UV Sterilizer or Ozone for disinfection (optional but common in drinking water applications)

Mineral Addition (optional, to re-mineralize the RO permeate water for drinking purposes)

Electrical Specifications:

Voltage: 380V / 3 Phase (Common for industrial systems)

Frequency: 50 Hz or 60 Hz, depending on location

Control Panel:

Automatic control panel with features such as:

Pressure gauges

Flow meters

System On/Off control

Alarm system for high/low pressure, membrane fouling, etc.

Membrane Housing:

Material: FRP (Fiber Reinforced Plastic) or SS (Stainless Steel) depending on system design

Wastage:

Reject Water Recovery: Typically around 25% to 30% of the feed water will be discarded as waste (depends on recovery rate)

Dimensions & Weight:

Size and weight vary depending on the design, but a typical industrial unit may be 2m x 1m x 1.5m in size and weigh several hundred kilograms.

Application:

Industrial Use: For production facilities, bottling plants, pharmaceuticals, power plants, etc.

Water Source: Can handle different water sources such as borewell water, river water, sea water (in case of desalination), etc.

System Configuration:

Standard 2 or 3 stage filtration (for multi-stage pre-treatment and post-treatment)

8,000 to 10,000 LPH RO

It looks like you’re asking for the specifications of a 10,000 LPH (Liters per Hour) industrial RO (Reverse Osmosis) system. To provide accurate information, I’ll outline some general specifications and features that are typically found in an industrial reverse osmosis system with a capacity of 10,000 LPH:

General Specifications of a 10,000 LPH Industrial RO System:

- Capacity:

- Flow Rate: 10,000 liters per hour (LPH) or 10 cubic meters per hour (m³/h)

Read More

- Pre-Treatment System:

- Multimedia Filtration (MMF): For removal of large particles like sand, silt, and sediment.

- Activated Carbon Filtration (ACF): For removing chlorine, organic compounds, and odors.

- Water Softener: For removing hardness (calcium and magnesium).

- Antiscalant Dosing System: For preventing scaling on RO membranes.

- Micron Filtration: To further filter out finer particles before the water reaches the RO membrane.

- RO Membranes:

- Membrane Type: Typically Thin Film Composite (TFC) membranes.

- Number of Membranes: Depending on the membrane size, this could be 6 to 8 membranes in series or parallel configuration.

- Membrane Capacity: Each membrane can typically handle 800-1000 GPD (gallons per day) per module.

- Pump:

- High-Pressure Pump: To provide the necessary pressure (typically 150-300 PSI) for the reverse osmosis process.

- Pump Type: Stainless steel centrifugal or plunger type.

- Recovery Rate:

- Typical Recovery Rate: 60%-85% depending on water quality and system design.

- Control and Monitoring:

- PLC (Programmable Logic Controller): For automated control and monitoring.

- Flow Meters: To monitor the feed water, permeate water, and concentrate water flow.

- Pressure Gauges: To monitor the system’s pressure across various points, including pre-treatment, membranes, and post-treatment.

- Conductivity Meter: For checking the quality of the treated water.

- Post-Treatment System:

- UV Sterilizer: To ensure microbial safety of the product water.

- Post-Carbon Filtration: For taste and odor improvement.

- Optional Mineralization: If the treated water needs re-mineralization, an inline mineral filter or dosing system might be included.

- Materials of Construction:

- Frame: Usually made of stainless steel or mild steel with powder coating.

- Membrane Housing: Typically made of FRP (Fiber Reinforced Plastic) or stainless steel.

- Electrical Power:

- Power Supply: Typically 380V, 50Hz (or customized as per the location).

- Power Consumption: Around 5-7 kW depending on the system efficiency.

- Product Water Quality:

- TDS (Total Dissolved Solids): The RO system can reduce TDS to below 10-50 ppm (depending on input water quality).

- Conductivity: Product water conductivity typically ranges from 10-100 microsiemens per cm (µS/cm).

- Purity: Typically, a rejection rate of 95-99% for salts and impurities.

- Safety Features:

- Auto Shutoff Valves: To protect the system from overflows or system failures.

- Leak Detection: To monitor and prevent water leakage from the system.

- Optional Features:

- Skid Mounting: For easier installation and mobility.

- Online Water Quality Monitoring: Real-time monitoring of water quality parameters.

This is a generalized overview. The specifications could vary based on the manufacturer and the specific needs of the application (such as feed water quality, desired output water quality, and operating environment). Would you like further details on a specific part of the system?

Our Industrial RO Solutions

Why Select an Industrial RO Plant?

Cost-Effective

Cut down costs while improving water quality with our efficient systems.

Eco-Friendly

Promote sustainability while reducing environmental footprint with our solutions.

Custom Solutions

Get tailored designs that cater to your unique industrial requirements.

Reliable Performance

Count on our tested systems for dependable and consistent water purification.